I have a Viewsonic model VG2230WM LCD monitor that has quit. I read that these monitors have the "Chinese capacitor problem" but I can't figure out what exactly that means and what to do to fix it. Do I just replace all the caps on the PCB?

#10144

Jouko Koskela

Memphis, TN

Please log in to post an answer.

Answers

Often a monitor goes dark because the back light power supply fails. Look for the power module which has the pink and blue wire back light voltage connectors. Usually there are two or four connectors for the backlight power. The capacitors on this module often fail due to heat over a period of several years, and they sometimes have bulging tops making them easy to spot. Replace all of the electrolytic capacitors on the power module, there may be five or six of them. In many cases this will restore operation of the monitor.

Bill Seabrook WETA-TV

via email

I have repaired several flat screen monitors, one of them was the VG2230WM. I was able to find the power supply on line and replace it after getting it open. Another one was fixed by buying the capacitor kit on line and replacing each of them. The hardest part of any flat screen repair is getting them open without damage.

Good Luck.

Bob Smith

Prescott, AZ

Is there a rule of thumb for when it is better to use carbon film resistors over metal film resistors?

#10143

Brayden Lawlor

Norfolk, VA

Please log in to post an answer.

Answers

Generally, if you require greater precision, better stability and/or less noise, you go with metal film resistors. In the olden days, this was an expensive option, but these days, precision metal film resistors have plummeted in cost, at least for the Asian imports. So use metal film if you're working with test equipment attenuators, voltage dividers and analog timing circuits.

Metal Film Is Better

If you need a circuit to remain within operational specs for a long time without periodic adjustment.

If you’re designing a low-noise audio preamp.

If you need precise timing for your 555 circuit.

Some notes here.

1 - The ancient trick of beginning with a carbon composition resistor of a lower value than needed and filing a notch in it until the value was right on, gave you a good, tight resistor for a few minutes. But even if that notch is sealed with clear fingernail polish, carbon resistors still have a lousy temperature coefficient. The resistor will change in value with any changes in temperature far beyond what you'd want with a precision part. It isn't the same as using a precision metal film resistor, no matter what that old timer tells you.

2 - The second note concerns power dissipation. The old carbon comp resistors could take short spikes in power and survive even with short bursts of ten times the power rating, because the mass of that slug of a resistance element could absorb and dissipate that spike. Carbon film and metal film resistors can handle their specified power level, but can't handle spikes well, for they don't have that same mass in the resistance element. They can dissipate the average rated power, but not absorb the heat of a big power spike. So, that same spike in power can cause a carbon or metal film resistor to literally burn out.

Even with the problem of film over composition described above, carbon film resistors do seem to have tighter and more stable values than the comps. They still suffer from bad temperature coefficients and noise, but the typical new 5% carbon film resistor will often be well-within 2% of its marked value.

Dean Huster

Harviell, MO

As a "rule of thumb" I recommend: Choose carbon film resistors when low cost (at high quantity) is the main consideration. Use metal film resistors when low noise, low temperature coefficient, and/or greater precision are important.

All types of resistors generate thermal noise, also called "Johnson noise," which increases as resistance and temperature increase. This comes directly from the laws of physics which, as Engineer Scotty famously said on Star Trek, "you canna change." However, current flowing through a resistor causes additional noise, including "shot noise," and this is greater in carbon film than in metal film types. That is why the latter are preferred for critical analog circuitry, such as audio preamplifiers. Resistor noise hardly matters in digital applications.

For more information about noise, see Joe Geller's excellent resistor noise measurement project (JCan) in the July 2007 Nuts and Volts. After building the JCan kit, I could easily measure more noise in carbon composition types compared to metal film resistors of equal value when current was applied. There was no difference with zero current — just the thermal noise "background." The noise difference between carbon film and metal film resistors under power was smaller, but detectable.

The temperature coefficient tells you how much a resistor's value can change with temperature, in units of parts per million (PPM) per oC or oK. Common axial lead (through hole) ¼-watt metal film resistors are rated 50 or 100 PPM/ oC, but their carbon film cousins are 350 to 700 PPM/ oC. Sensitivity to temperature is a consideration in many sensor and measurement applications, but it does not matter in digital circuits.

Assuming the resistor offerings at Mouser Electronics (www.mouser.com) are typical of the industry, the vast majority of ¼-watt axial units are available only at 1-percent tolerance for metal film, and 5 percent for carbon film. Even if I wanted one, I could not buy a 5% metal film or a 1% carbon film resistor. Therefore, choice of type is related to precision, for practical purposes. The cost difference is negligible for small quantities; you are mainly paying for the labor to count them out and bag them.

Clark Huckaby

via email

I'm not sure about a rule of thumb but I would not use metal film resistors in an RF circuit. It would be my luck that I create a resonate circuit and have all kinds of strange oscillators going. Good Luck

Bob Smith

Prescott, AZ

I recently inherited a 1980's era Commodore SX-64 computer. Though it looks cosmetically perfect, it doesn't power up (i.e., the little monitor lights up with a plain gray color, but there is no sound or picture). Anyone have any pointers on where to begin troubleshooting this unit?

#10142

Dani Sanders

Salt Lake City, UT

Please log in to post an answer.

Does anyone have a simple circuit/schematic to use a 555 timer to dim a 120 VAC incandescent bulb? In the little bit of research I've done, it seems like using the 555 for PWM should do the trick, but I don't understand "zero crossing" and why it’s important. Pointers welcome!

#10141

Chuck Pearson

Kansas City, MO

Please log in to post an answer.

Answers

I have a 555 PWM circuit diagram on one of my YouTube videos here: [url=http://youtu.be/KrcqpGZQd9U?list=PLUsDZdokq6wxDP7L3sMoYFTA5WDoAtBu4]http://youtu.be/KrcqpGZQd9U?list=PLUsDZdokq6wxDP7L3sMoYFTA5WDoAtBu4[/url] The diagram is at about 2:18 in the video. I hope it helps for starters...

Freddy Cordero

via email

Is there such a thing as a noise cancelling technology that would allow me to play my guitar without disturbing the neighbors?

I get complaints about noise from my apartment when I play. I just can't use headphones and I've tried putting blankets on the wall for soundproofing, but I still get complaints. How about an electronic solution?

#9143

Brian Tate

Madison, WI

Please log in to post an answer.

Answers

There is no practical noise cancelling technology on that scale. Building an anechoic chamber would be very expensive. Playing guitar in a vacuum would not allow you to hear yourself (since sound does not travel in a vacumn), and would suffocate you. That leaves two possible options:

Relax your ban on headphones and use a product such as the $40 Amplug [The headphone guitar amp that lets you enjoy serious guitar sound, fast.] See www.voxamps.com/amplug or possibly the low tech solution of playing under a wool blanket.

More than 40 years ago we wanted to record short skits for radio brodcast in our college dorm room. Our input was not as loud as an accoustic guitar, and we were close mic-ed for voice and sound effects. We had such good sound isolation, that it effectively blocked the external noise of nearby stereos, running feet, shouting, and anti Vietnam War riots outside the building. Many people wondered where we found such a quiet place to record! This probably will not work for amplified electric guitar. You could use a self standing tent, with covering heavy bankets down to the floor. The level ouside the tent will be dramatically attenuated.

Barry Cole

Lacey, WA

I'm been working a lot with high power LEDs now that they're so affordable. I'm especially fond of the UV LEDs for visual effects at night, but I've heard that some UV LEDs can cause blindness, and that I should use a UV bulb to create the effects. Is this true? Can someone explain the difference?

#9142

Nick Robbins

Ft Wayne, IN

Please log in to post an answer.

Answers

The safety difference between a UV light bulb and a UV LED stems from the difference in radiance between the two sources. Radiance is basically the density of light in the source.

The surface area of an incandescent-size lamp is approximately 100,000 sq-mm. The source area of a high power LED is perhaps 2 sq-mm. While its likely a single high power LED will produce less optical energy than the bulb, the radiance is still likely thousands of times greater for the LED and hence its greater potential for eye damage.

In practice, as long as you don't look directly at the light source but rather the light reflected from the objects of interest, there is little difference between the two sources.

Steve Paolini

via email

Is there a CMOS op-amp with low noise, good common-mode isolation, and unbalanced output available? I would like to use it in a loop antenna preamp in a location that has an extremely high power-line noise level.

E-mode whips with a preamp are definitely unusable. This antenna would be untuned and intended for use below 30 MHz.

#9141

John R. Seeley KI4LTB

Palm Bay, FL

Please log in to post an answer.

I'm thinking of building a solar charger for my iPhone, but don't know how to handle the internal lithium battery in terms of taper current, etc. — especially when I have the phone on all day. What I've found online is information on charging disconnected lithium batteries, not ones under load. Any hints?

#7143

Anthony Suchek

White Plains, NY

Please log in to post an answer.

Answers

First, under load shouldn't be that much different from being off as long as the circuit can handle the current needed to do both jobs. That you will need to measure and then find a pre-built circuit to do the trick.

I suggest pre-built since they are so cheap. I did the same kind of thing for a phone that refused to recognize its own charger as a valid charger. A good ol' Motorola phone, I'll never buy another phone that has some type of recognition routine in it to check the charger.

In any event, the first thing I noticed was that my camera charger was for the same type of battery, same voltage, same AHr rating, same Li Ion battery. I hooked up wires from the charger into the phone and it worked just fine.

Next I wanted a more universal Li-Ion battery charger & found more than one on-line. The one I settled on was from dx.com:

1A Lithium Battery Charging Module - Blue $1.70/e

[url=http://dx.com/p/1a-lithium-battery-charging-module-blue-205188]http://dx.com/p/1a-lithium-battery-charging-module-blue-205188[/url]

There are others as well, a Red at 3A for under $9

[url=http://dx.com/p/1a-lithium-battery-charging-module-red-318740]http://dx.com/p/1a-lithium-battery-charging-module-red-318740[/url]

These are circuit cards usually with a USB power port to give it 5V 1A to work with, so you will need to do some soldering for connections to the battery from the board.

At 1A, expect to charge and run your phone without a problem, since most cell phones, even on transmit, are below 1W output. see: [url=https://en.wikipedia.org/wiki/Mobile_phone_radiation_and_health]https://en.wikipedia.org/wiki/Mobile_phone_radiation_and_health[/url]

and

[url=http://hypertextbook.com/facts/2006/EbruBek.shtml]http://hypertextbook.com/facts/2006/EbruBek.shtml[/url]

Phil Karras, KE3FL

Mount Airy, MD

Charging your iPhone should not require any special accomodations. The OEM charger from Apple supplies 5V at 1A via a USB connection with proper cable. Either the 30 pin connector or the new 5 pin "lightning" connector cable both deliver the same power.

The phone (as all phones now) has built in current limiting, temperature sensing and voltage sensing to protect the battery.

You just need to deliever 5V, regulated, to the cable with, of course, polarity protection for the solar charger. A simple LM7805 regulator IC is what most chargers use for the 5V.

It really is NOT a good practice to leave the phone on the charger continually, as most rechargable batteries 'like' to be excercised. Charge it up, let it run off battery until it shows recharge is needed then reconnect charger. You should get several years of service from it.

Rod Hogg

Scott City, KS

I have an old car that came with electric windows but has old fashioned side view mirrors which are almost useless. I would like to upgrade to more modern mirrors that are aimed by control of 12V electric motors. On the driver's side, that is no problem as you simply use a four-way switch scavenged off the vehicle that you got the mirrors from, using the 12V available to run the electric windows.

However, to use that same switch to control the right hand mirror, I would have to drill a hole in the edge of both doors and both front pillars, and snake a wire through from the left side to the right side. It occurred to me that the use of radio waves from the left hand door could be used to control four relays in the right hand door and obtain the required action.

Something like Ron Newton used in his “Super Detector” article in the October 2013 issue of NV. Any suggestions would be appreciated.

#7142

Dean Kaul

Kalamazoo, MI

Please log in to post an answer.

Answers

I would like to know if I have correctly connected the photoresistors (CdS photocells) shown here in order to turn OFF during the day and to turn ON during the night the two LED circuits attached to them. (If not, please indicate by a new diagram.)

Also, I would like to know:

a) If any photoresistor would work?

b) What would the optimum dark/light resistance values be for such a photoresistor?

c) How would I calculate the values (any formula?) from the transistor side (2N2222) that would best fit this ON/OFF photoresistor switcher?

#7141

Nate

via email

Please log in to post an answer.

Answers

Depending on the current required by the different LED loads, the value of the Cds sensor is critical. In addition, you should include hysteresis to snap the load ON or OFF, rather than have it operate erratically at the dawn or dusk threshold. If the Cds sensor has a large value at the critical threshold, there will not be enough current to bias the transistor ON to it’s saturation state.

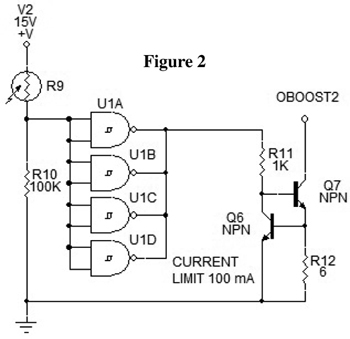

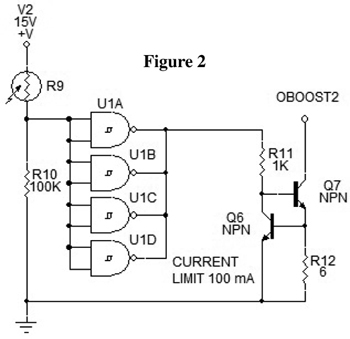

To remedy this problem, I have included two circuits which solve your issues. Figure 1 uses two transistors with positive feedback to create the needed hysteresis and gain to drive an output stage that provides 100 mA current limiting in case your load circuit shorts out.

Figure 2 circuit uses a 4093 quad-nand schmitt trigger (that has 1 volt hysteresis) and drives the same output stage as circuit one. The second circuit is probably the easiest one to implement, but requires the fourteen-pin 4093 IC. You will still need to select the a Cds cell that has around a megohm of resistance when dark and 10K or less resistance when light. Hope this helps you.

Ron Hoffman

Solon, OH

Power supply not specified.

Top circuit operating range using common 555 is from 5 to 15 volts by data sheet. IC 4017 data sheet specifies current drive limit about one milliamp. Some amplification required to drive LED at 10 to 20 milliamps

Bottom circuit requires at least 12 volts to operate series string of LEDs. Three LEDs in series add up to: G(3.2) + R(1.8) + G(3.2) = 8.2 volts. Requires at least 12 volt power to allow for current limit resistor voltage drop. LEDS will load down ring oscillator as shown. Need high impedance buffer to isolate LEDs from Resistor Capacitor time constant.

a) The logic of operation of CDS photocells is:

No Light = high resistance

Max Light = Low resistance

As shown, that logic will tend to turn on the transistor during the daytime and turn it off during the night. Simple solution is to swap 100K resistor with photoresistor in circuit. You will probably need to adjust resistor values to operate the way you require. You also need to limit current into the base of the transistor.

Not every photoresistor will work as the range of resistance variation must match the required transistor bias. You could measure the resistance of the photo resistor with an ohmmeter for both dark and light environment or look up the data sheet from Digikey, Mouser or the manufacturer.

See above circuit from Linear Technology Spice program.

Some CDS photo resistors are about 200K ohms in the dark and about 4K ohms in light. If the range is less, the transistors will always stay on. Measure the photoresistor in light with an ohmmeter. Cover the photo resistor to measure dark resistance.

b) Optimum bias would provide about 0.6 to 1.0 volts or more at the transistor base (relative to emitter) to turn on and less than that threshold to turn off. Depends on required current from collector to emitter.

You did not specify your power supply voltage. The 555 IC works best from about 5 to 15 volts. Three LEDS in series need at least 12 volts as shown.

Two red LEDS and 470 ohm minus (diode drops and IC drop)

(12 - (1.8 + 1.8)volt-1 -1 )= 6.4 volt

Max current = 6.4 volt / 470 ohm = 14 milliamps

The three LEDS with 1K resistor operating at 10 milliamps would require

VDC = (0.01 Amp * 1000 ohm)+(1.8)R+(3.2)G+(3.2)G 8.2

12 - 8.2 = 3.6 volts 3.6 volt/ 470 ohm = 7.6 milliamps

R8 is 330 ohm for 10 milliamps

Current limit for 4017 source about one milliamp out. need transistor drivers.

470 ohm drive about 14 milliamps

Ring oscillator may not work as LEDs are loading RC timing, transistor emitter followers may help. Linear Technology Spice program can be used to experiment with different values.

Calculation for transistor bias

R1 = base to power bus VCC

R2 = base to ground or common

Vbase = VCC * (R2 / (R1 + R2) )

This is first approximation as some current will go into base of transistor. Switch point is about in the range from 0.6 to 1.0 volts

High on , low off

Look up Ohm's law

See attached circuits

The .PDF extension is directly viewable. The .asc format is editable within Linear Technology Spice. LTSpice is free and downloadable from Linear Technology web site

Adjust the photo resistor value for the version you have at light and dark environment. Verify that the LOAD has a reasonable current (ON value) of about 10 to 100 milliamps or negligible current (OFF value)

Edward Wade

via email

The two circuits Nate submitted are configured to turn the LED sequencers ON during the day and OFF at night. This is because the resistance of the photocell decreases as light falling on the photocell increases, causing increased current flow from the base of the transistor to the positive power supply rail. The increase in base current will cause the transistor to conduct and supply current to the LED sequencer circuits in daylight. To modify the circuits so they turn OFF during the day and ON at night, swap the photocell and the resistor so that decreasing photocell resistance will pull the base of the transistor toward ground, turning the transistor off in the daytime. The fixed resistor will turn the transistor on at night when the resistance of the photocell is high compared to the resistor. The circuit can be improved (see new diagram in Figure 1). Two issues are solved by the improved circuit.

1) Nate is using a 2N2222 transistor as a low side switch to control current to the light sequencer circuits. A MOSFET makes a better switch because it has a very high OFF resistance and a very low ON resistance, so more of the supply voltage is applied to the light sequencer circuit and less power is wasted in the transistor. For this reason, I replaced the 2N2222 transistor with a low cost IRF510 N-channel power MOSFET.

2) The other problem with Nate's circuits is they won't turn on and off quickly like a mechanical switch. At dawn and dusk — when the light changes gradually — the current through the transistor will also change gradually. The switching action should happen fast when a predetermined light threshold is crossed; a Schmitt trigger circuit is needed for that. The improved circuit contains four Schmitt trigger NAND gates in a single 4093 CMOS IC. Only one NAND gate is needed, so the other inputs should be tied to V- to prevent instability.

The 4093 has a hysteresis band which keeps the sequencer circuit from receiving rapid bursts of current at dawn and dusk when the control voltage hovers near the tripping point. The output of the 4093 drives the IRF510 MOSFET which switches the current to the LED light sequencer circuit on and off. The MOSFET is driven into saturation by the 4093 Schmitt trigger to provide clean switching and maximum current to the LED sequencer circuit. Next, the answers to questions a, b, and c.

a) Will any photoresistor work?

Most photocells will work with the improved circuit, but don't confuse a photocell (which is a photoresistor) with a phototransistor. I've included a pot wired as a variable resistor; this will adjust the voltage divider to match the photocell characteristics. To set the pot, go outside in the twilight near sunset and adjust the pot until the circuit turns ON, then back off slowly until it turns off. The LED sequencer circuit should then turn on at sunset and off at sunrise.

b) What are the optimum photoresistor light/dark resistance values?

The resistance of most photocells varies from a few hundred ohms (or less) in direct sunlight to a megohm (or more) in total darkness. The optimum resistance of R1 for a given photocell can be calculated using Ohm's Law, but the adjustment pot in the improved circuit makes it compatible with most CdS photocells.

c) What formula will calculate the optimum component values?

The 2N2222 transistor used in Nate's circuits is a current operated device which should be explained in terms of current. The improved circuit uses voltage controlled components. This explanation is only for the improved circuit.

Inputs 1 and 2 of the 4049 are tied together and connected to a voltage divider consisting of photocell PC1 and resistor R1, which are connected in series between V+ and V-. To predict circuit operation in different lighting conditions, calculate the voltage from V- to the point where R1 and PC1 join using Ohm's Law, and then compare this voltage to the upper and lower trip points of the 4093. The lower trip point will turn the LED sequencer circuit on because the 4093 is an inverter, which will drive the gate of the MOSFET to V+ when the 4093 input is low. When the MOSFET conducts, it will ground the LED sequencer circuit to V-. The lower trip point of the 4093 is +3.9 volts when V+ is 10 volts and the upper trip point is +5.9 volts.

EVENING CONTROL: The voltage across R1 must fall below 3.9 volts to turn the LED sequencer on at sunset; this example uses 3.5 volts to be well below the threshold. To calculate the optimum resistance of R1, it's necessary to know the resistance of PC1 in the twilight hours of sunset or dawn.

This example assumes the resistance of PC1 is 100K at sunset. The voltage drop across both resistors must add up to V+. So, if V+ is 10 volts, then 6.5 volts must be dropped across 100K (PC1) for 3.5 volts to be dropped across R1. Operation of the improved circuit is explained in four steps.

STEP 1: Calculate the current through the voltage divider at sunset.

If we know the resistance of PC1 and the voltage across it, then we can calculate the current through PC1 with Ohm's Law (I = E/R). Plugging in the known values, I = 6.5/100,000 = 65 µA. This is a series circuit, so 65 µA also passes through R1.

STEP 2: Calculate the resistance of R1.

We know the current through R1 is 65 µA and the voltage across R1 is 3.5 volts, so we can use another form of Ohm's Law (R = E/I) to calculate the resistance of R1. R1 = 3.5/.000065 = 53846 ohms. To check this, use E = IR, E = .000065 (53846) = 3.499 volts; 3.5 volts is under the lower trip point of the 4093, so output pin 3 of the NAND gate will go high, driving the gate of the IRF510 MOSFET to V+ through R2. This causes the MOSFET to conduct and provide a current path from V- to the LED sequencer circuit.

MORNING CONTROL: At the soft light near daybreak, a typical photocell has a resistance around 10K. If we use the value of 53.846K previously calculated for R1 and assume a PCI resistance of 10K at dawn, then the total resistance of PC1 + R1 is 10K + 53.846K = 63.846K.

STEP 3: Find the daytime current through the voltage divider.

If V+ is 10 volts, the current through the series resistances PC1 and R1 at sunrise can be calculated with I = E/R. I = 10/63846 = .0001566 A, or 157 µA.

STEP 4: Find the daytime voltage drop across R1.

Now that we know the morning current through R1 and the resistance of R1, we can calculate the morning voltage drop across R1 with E = I/R; E = .0001566 (53846) = 8.43. A daytime voltage drop across R1 of 8.43 volts is well above the 5.9 volt upper trip point of the 4093, so the output of the inverting 4093 will go low, grounding the gate of the MOSFET to V- and turning off current to the LED sequencer circuit. During the day, the input to the 4093 should vary between 8 and 10 volts, keeping the LED sequencer circuit turned off.

Ed Gore

Panama City, FL