I picked up a "hum blocker" for my guitar amp, only to discover that all it does is disconnect the ground from a three-prong outlet.

It seems to work. The hum — whether from a ground loop or pickup from fluorescent lights — is much less noticeable. My question: Is this device safe to use?

#1141

Steven Sewal

via email

Please log in to post an answer.

Answers

Some comments and concerns regarding your question. First, I am not clear if this is a repair or a retrofit. I would also presume this is a tube-type amplifier, since they were often built with point-to-point wiring and hum pick up was highly likely with so many signal wires running around the chassis.

Based on your comment of "adding a kit", I would presume that either this is a retrofit or the original noise filter cap was removed in the past. The fact that adding the new cap from line to ground reduced the 60 cycle hum (or 120, depending on the rectifier design), it seems that this might actually be a repair. Or, the filter caps themselves are old and leaky, so you are aiding them but not actually curing the problem. If the amp is old, it often needs to have the filter caps replaced and, sometimes, some interstage decoupling caps as well.

With that background, I caution that this involves principles of safety and if you are not experienced with working on mains circuits, this effort would be best left to a professional. Just because something works does not mean it is well-executed or robust. And since guitar amps get moved, jostled, banged around and often not treated caringly, there is a chance your soldered connections of this component could break loose without your knowledge and you could have a real shock hazard on your hands.

OK, assuming all that is well-appreciated, the type of cap you use is critical. This component is connecting one side of the AC mains to the accessible chassis. You cannot assume that a ground pin on a cord will save your life since you have no idea how well the ground-to-neutral impedance is controilled in the building's branch circuit you just plugged into. Hence, the cap itself must be suitably rated to be connected from line to ground. Therefore, this must be a Y2 type of cap.

If you have no idea what a Y2 cap is, then read this link first: www.justradios.com/safetytips.html. There are many good manufacturers of Y2 caps (Vishay, KEMET, Panasonic, etc.). Here is a good selection from Mouser: www.mouser.com/new/Kemet-Electronics/KEMET_XY_Film_Caps.

Be sure that you do not rely on solder for mechanical support of live parts. Always wrap the cap leads snugly around the terminals it is connecting to and check to determine that it would tend to stay there if no solder was used. Solder is not meant for mechanical retention of massive parts. Once you feel it is well mounted, then use solder to make the electrical connection to the terminals.

Jon Kalfus

Red Bank, NJ

Safe is a relative matter of degree. The safety ground wire in a standard three wire AC cord is there for a reason. However, the NEC does allow for devices that do not have that safety ground connection. Many electric and electronic devices are made without it.

The safety ground connection is there to insure that the fuse does blow or the circuit breaker does trip if a conductive outer case of the device becomes electrified. The current that flows from the hot wire to the safety ground blows the fuse or trips the breaker and then there is no danger of shock.

Devices that do not have that safety ground usually employ a double insulation method to prevent such a short to the outer case or to the user. Thus, if there is internal insulation AND the outer case is an insulating material like plastic, then TWO different insulators would have to fail for the user to get shocked.

Older devices, like early electric lamps, were made with metal outer cases and often the electric wires inside them were only a small fraction of an inch from that conductive case. Older electric cords were insulated with real rubber which deteriorated over time and became "frayed". The card board insulators in lamp sockets literally fell apart after some years of service, usually with over sized bulbs in the lamp (rated at 40 W so the user put a 60 or a 100 W for more light). Etc., etc., etc.

It is not possible to tell if a particular device, like your amplifier, is safe without examining it. If it was commercially manufactured in the US or imported properly, then chances are it is OK. Things like the UL (Underwriter's Laboratories) tag are supposed to tell the consumer that it has been inspected and found to comply with the code. If it is a kit or was made in someone's kitchen or garage, then it may or may not be OK.

Hum like this, is usually a result of what is called a "ground loop". Both the signal cable between the audio devices and the power cables to them are grounded and they form two different and distinct ground paths between them. If there is any 60 Hertz current flowing in either of them, then the circuit/signal ground planes in each of those devices will be at a different AC potential and the hum is introduced into the signal.

One way of eliminating this situation is to cut the safety ground on one or both of the devices. But this eliminates the safety feature of that connection. A better way to eliminate this situation is to use a balanced audio line between the devices and to connect (ground) the shield only at the source end of that line. In this way there is only one ground connection between them, via the AC power. Many times this is used in professional audio installations where long lines must be run. But this may not be possible on amateur equipment where single ended audio lines are often run.

Another solution is to use a differential input amplifier at the receiving end of the audio line. This can be accomplished with a transformer or with actual active circuitry. With a transformer, the center lead and the shield of the single ended cable are connected to the primary of the transformer so the shield is not connected to the chassis/signal ground of the amp.

Active circuitry with a balanced input is more complicated. I am designing such an amp at the present time to overcome a noise problem between my audio/visual equipment cabinet behind my chair and the computer on the desk in front of it. Due to the arrangement of the room, I had to run a 50 foot cable and it does pick up hum.

An audio transformer of sufficient low frequency response would cost a bundle. Since the audio is single ended (not balanced) this may be the only solution. I have searched and could not find a reasonably priced, differential input audio amp for this application. Professional ones seem to start in the hundreds and go up from there.

Another factor that helps to overcome noise and hum is the impedance of the audio line. Much amateur equipment uses a high line impedance which may be OK for a few feet, but longer, high impedance (10 KOhms) lines will pickup noise and hum from the environment. Professional audio uses lower impedance lines to overcome this.

The old standard was 600 Ohms but modern equipment often has extremely low output impedance (one Ohm or less) and a higher input impedance. This works in most situations. When long lines need lower termination impedance on the receiving end, a simple resistor can be connected across the line at that point.

Paul Alciatore

Beaumont, TX

I have two sets of LEDs; eight LEDs in each set. The sets need to turn on alternately. However, I would like the brightness to turn on gradually, then fade out. Then, the second would turn on and off in the same manner.

#12084

Arsen Dedic

Palm Springs, CA

Please log in to post an answer.

Answers

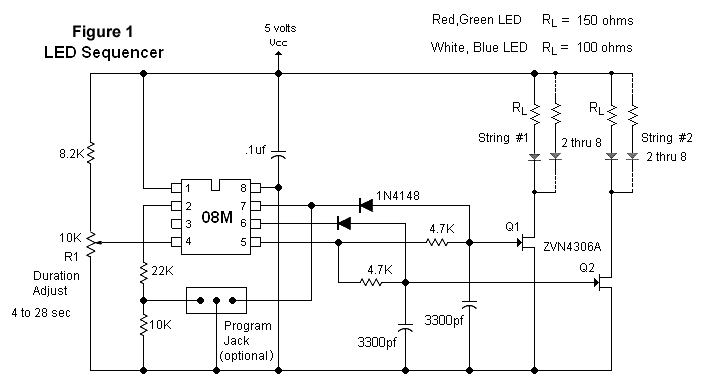

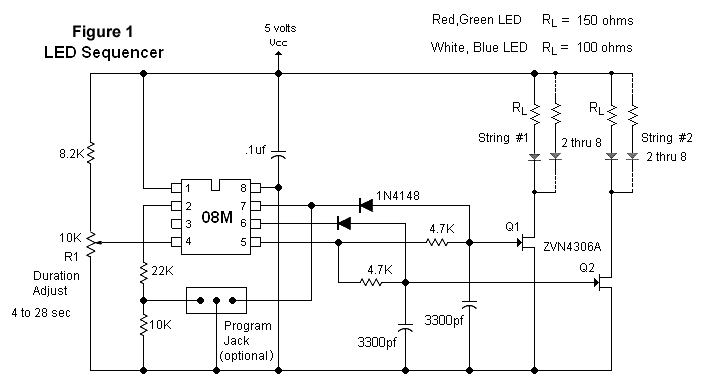

As far as controlling the LED brightness, here are two possible solutions: one using PWM (pulse width modulation) and the other a variable DC power source. First, I'll describe the PWM circuit in Figure 1 which is controlled by a PICAXE 08M microprocessor. The output from a PWM generator is programmed to run continuously. The timing duration is controlled by the ADC reading on potentiometer R1. The LEDs are controlled by FETs Q1 and Q2. All parameters are set by the programming code.

As far as controlling the LED brightness, here are two possible solutions: one using PWM (pulse width modulation) and the other a variable DC power source. First, I'll describe the PWM circuit in Figure 1 which is controlled by a PICAXE 08M microprocessor. The output from a PWM generator is programmed to run continuously. The timing duration is controlled by the ADC reading on potentiometer R1. The LEDs are controlled by FETs Q1 and Q2. All parameters are set by the programming code.

main:low 1 ' LED set #2 off<br />

high 0 ' LED set #1 on<br />

readadc 4, b2 ' read voltage and set duration time, b2 varies from 4 to 28<br />

let b2 = b2/5 min 4 ' duration time = 500 * b2 * 2<br />

for w0 = 0 to 500 ' duty cycle scans from 0 to 100%<br />

pwmout 2,124,w0 ' frequency set at 8KHz, output leg#5<br />

pause b2 ' LEDs brighten during this for-next loop<br />

next w0<br />

for w0 = 500 to 0 step - 1 ' Leds dim during this for-next loop<br />

pwmout 2,124,w0<br />

pause b2<br />

next w0<br />

<br />

low 0 ' LED set #2 on<br />

high 1 ' LED set #1 off<br />

readadc 4, b2 ' read voltage and set duration time, b2 varies from 4 to 28<br />

let b2 = b2/5 min 4 ' duration time = 500 * b2 * 2<br />

for w0 = 0 to 500 ' duty cycle scans from 0 to 100%<br />

pwmout 2,124,w0 ' frequency set at 8KHz, output leg#5<br />

pause b2 ' LEDs brighten during this for-next loop<br />

next w0<br />

for w0 = 500 to 0 step - 1 ' Leds dim during this for-next loop<br />

pwmout 2,124,w0<br />

pause b2<br />

next w0<br />

goto main ' repeat code

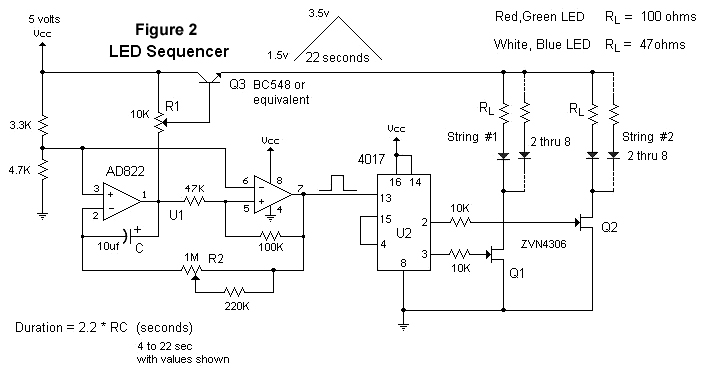

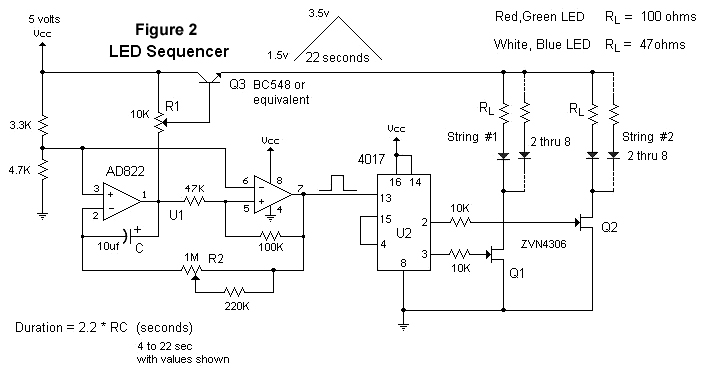

Figure 2 uses a combination triangle-square wave generator (U1) to control the variable DC voltage from Q3. R2 controls the duty cycle and R1 controls the minimum DC output from Q3. The setting of R1 will depend on the color and/or type of LEDs used. Basically, R1 is adjusted so the LEDs just shut off before the counter advances. The square wave output (pin7 of U1) is used to advance the 4017 (U2) which is configured as a count to two and recycle counter. The square wave output switches low at each minimum crossing of the triangle generator. This is used to control the "clock enable" (pin 13) on U2. The clock input is connected to Vcc so the counter will advance each time pin 13 goes low. One nice feature about this circuit is the 4017 allows for easy expansion (up to 10) if more LED strings are needed.

There were no details mentioned about the LED strings regarding how they are wired, the color, or voltage needed. In this case, I decided to show both circuits operated with the LEDs in parallel with individual current limiting resistors. The RL values shown are only guidelines as the specs on the LEDs and the brightness required by the user will vary. Both circuits require a regulated 5 VDC power source.

Steve Ghioto

Jacksonville, FL

My latest creation, a 50W tube amp, produces great, audiophile-quality sound. Problem is, I have two fans cooling the amp, and the noise is distracting. Is there an alternative to forced-air cooling of audio tubes? I've looked at the water cooled systems used for computers, but I don't know if the tubes are too hot for a DIY water jacket.

#12134

Jasper Stevens

Birmingham, AL

Please log in to post an answer.

Answers

You could use a squirrel cage fan. It is a lot quieter for the same airflow.

Lance Corey

Santa Ana, CA

Back in the day when there were ONLY tube amps, none of them used fans. Hot air rises and tubes make the air hot enough that convection cooling is all that is needed as long as you properly ventilate the box containing the amplifier. This means long slits, or a large amount of nice sized holes, in the bottom and the top of the box to let the air flow.

Phil Karras, KE3FL

Mount Airy, MD

I want to encapsulate a circuit board with a small Li-ion battery in epoxy, for an outdoor, weatherproof project. Does anyone have experience encapsulating batteries? Is this a good idea?

#12133

Rich Strunk

Houston, TX

Please log in to post an answer.

Answers

LiPo batteries which are probably what you are wishing to use do not like to be compressed, flexed, or prevented from expanding slightly during use. Encapsulating them in epoxy directly could do any and all to it, since the thermal expansion coefficient of the epoxy would differ than that of the battery.

There are other options, one of which is the inexpensive Lexan cases intended for protecting cellphones while camping sold at Walmart or other such stores. They have a silicone seal and clamping latch that protects the contents from moisture. If you needed to bring in signals or power, one could drill a hole, then feed the wire through and use RTV (silicone) to re-seal the hole. If you do this, route the wire from the bottom and drill a small drain hole that is at the lowest point. Air can pass through the cable itself, over time enough water vapor could collect in the case to become a problem under certain weather conditions.

Arlen Raasch

Fredericksburg, VA

Epoxy encapsulation is pretty drastic. Why not simply seal things in a plastic screw top container?! If the explosive nature of Li-ion cells is the concern, then you may be better off using the far more tolerant 3.2V rechargeable LiFePO4 (Lithium Iron Phosphate) version.

AA/AAA sized LiFePO4 cells sell for ~US$5 each, and are stated as good for 1000s of charge/discharge cycles too. See www.instructables.com/id/Single-AA-LiFePo4-cell-powered-project-in-a-parti/

Stan Swan

Wellington, NZ

I use one of those headlamps alot and replacing the batteries is getting expensive. Are there affordable rechargeable batteries that provide the same burn time as single use batteries?

#12132

Al Stipen

Miami, FL

Please log in to post an answer.

Answers

Are there ever! Rechargeable 3.2V Lithium Iron Phosphate (LiFePO4) cells are surely the answer. They're powerful but safe, very lightweight and available in both AA & AAA sizes at ~US$5 each.

Perhaps best of all is that one will replace two 1.5V alkalines (or 3 NiMH!).

Simple placeholding dummy cells can pad out the battery bay. I've taken to using these in my Canon digital cameras to great effect.

Stan Swan

Wellington, NZ

I'm working on a robot project that requires navigation and I'm trying to decide between an accelerometer and a gyroscope chip. Accelerometers are cheaper, but I've heard not as accurate. Is this true? When should I use one over the other?

#12131

Steve Coldwell

Topeka, KS

Please log in to post an answer.

Answers

They are two different sensors. A gyro measures rotation about an axis. An accelerometer measures acceleration in a given direction. To create a true inertial navigation system, one needs to accumulate both acceleration and rotation information in all three axes (x, y, & z). An accelerometer can be used to make a rotation measurement. It will not be as accurate as traditional rotation sensors.

Nevertheless, for making "guidance" sensors as opposed to "navigation" sensors, there are many (relatively) inexpensive three axis monolithic sensors based on MEMs accelerometers. Guidance is used to provide orientation feedback whereas a navigation sensor is used to place location after so many seconds, hours, or days.

For further study on the differences, look at the physics behind a ring laser or fiber optic gyro (it only takes a few minutes to figure out what is going on). The difference in what the sensors are measuring becomes apparent ([url=http://en.wikipedia.org/wiki/Ring_laser_gyroscope]http://en.wikipedia.org/wiki/Ring_laser_gyroscope[/url]).

D Ferguson

Austin, TX

This has to do with electrolytic aluminum filter caps for switching power supplies.

No matter what type filter cap I try, they blow out (become pregnant) after months or a few years. I repaired cable boxes for many years that had the exact same problem.

This is only a three volt supply at about two amps. Ten volt 1,000 mfd caps are used in the stock supply. Also, a three amp Schottky diode (burns up) supplies the DC to a 15 amp logic N-channel MOSFET with a heatsink. It gets hot. Then, the output of it gets a cap, a choke, and a cap. Nicely filtered three volts.

This is my final change-out and it is lasting the longest. So far, no blow outs, but it has only been seven months.

Now, the two five amp Schottky diodes in parallel. Using only one still gets super hot. Caps 25 volt at 1,000 mfd. I’m only using general type filter caps at 20% 105° C. Why has this been such a big problem?

The cap that usually blows is the first one after the MOSFET. I see no spikes on the output of the MOSFET either. I could use a TO-220 pack with dual diodes in it, but no room. The two 5 amp in parallel work just great and only get warm.

#11133

Dan Zielinski

Port Saint Lucie, FL

Please log in to post an answer.

Answers

The likely cause is the high-frequency ripple; aluminum electrolytic capacitors don't deal well with high frequencies (high loss factor) or large AC component of a waveform (capacitor may be depolarized).

He could substitute a tantalum capacitor, and/or parallel some ceramic capacitors across the aluminum one, e.g. 0.01 µF and 0.5 µF (or 10 nF and 500 nF, if you prefer), keeping the leads of the ceramic capacitors short. He could also use a small ferrite choke in series with the capacitor to decrease the AC component of the waveform.

A schematic of the power supply would help to pinpoint the problem.

Bart Bresnik

via email

The quick answer to your inquiry is that you're using the wrong type of filter capacitors.

From the description given of the power suppy — three volts, two amperes (6 watts), and the heating problems encountered, I surmise that you have a small flyback switching power supply that is not operating very efficiently. If the supply is rated for a mains input range of 90-130 volts AC and you're operating near the top end of that range — 120 volts or so — the ON time of the switch transistor will be quite short relative to the OFF time. All of the input power to the flyback transformer must be delivered during that short ON time, so the switch current will be high. Similarly, the flyback (secondary) current pulse through the output diode will be high because it must deliver all of its energy to the output capacitor in a short time. Both of these conditions serve to elevate the operating temperature of the switch transistor and output diode.

Finally, that output current pulse is dumped into the output capacitor. A real capacitor can be visualized as an ideal capacitor in series with a small resistance; the latter is known as the Equivalent Series Resistance (ESR). You need to use capacitors having a very low ESR value and a high ripple-current rating. I would expect that your output capacitors are seeing very high instantaneous ripple currents. Capacitor heating is a function of the ESR value and of the square of the rms value of the ripple current. A suitable capacitor might be a Panasonic EEU-FR1E102, available from DigiKey, their part number P14424-ND, $0.91 each. The ESR of this device is 0.020 ohms and it will tolerate over 2 amperes rms.

As far as paralleling diodes goes, I've had bad experience with that. You cannot guarantee exactly when the diode will switch from non-conduction to conduction, so for a very short instant, one diode may be exposed to the full current pulse. I can't visualize why you have room to fit two 5-ampere Schottky diodes but not room for one 10-ampere TO-220 package.

The reason that the capacitor nearest the MOSFET switch is the first to be destroyed probably relates to the board layout, and the fact that the other capacitors have additional lead inductance (including the etched conductors) in series with them. If possible, try to equalize distribution of current from the switch to each of the capacitors, and do the same for their returns to the Common bus.

I hope that these suggestions help.

Peter Goodwin

Rockport, MA

I want to rotate one 40 lb metal triangle up 90°. Its base will be connected by a hinge to the base of another triangle. The base is 67.88"; the other legs being 48", and a height of 57.87". By rotating the apex of the triangle 90°, the apex would travel an arc by 8.18 ft. I intend to use two sprockets and a chain connected to a motor. What size motor will I need to use to complete this and how is it determined? I understand w = fd and P = fd/t. I would like the time to be six seconds.

Can someone please help with the answer and also show me how to figure this problem out for myself?

#11132

Derek

OK

Please log in to post an answer.

How does a Tesla coil actually work? I’m especially interested in the relationship between the primary winding and secondary winding that creates the spark.

#11131

Brian Miller

St. Paul, MN

Please log in to post an answer.

Answers

The Tesla coil uses a resonant transformer, with tuned primary and secondary coils, to produce high-frequency current at very high voltage. A resonant transformer is like a child's swing, or pendulum; by pushing repeatedly at just the right time on each cycle, the pendulum can be made to swing much farther than from any one push. Also, as in the case of a pendulum, the trick is to give a short, sharp push and to let go, which may be done in a Tesla coil using a spark gap that is conductive for only a part of the cycle. When the circuit is broken, the high dv/dt (rate of change of voltage) in the inductance of the primary circuit creates a high-voltage wave. In addition, like any transformer, the Tesla coil multiplies the output voltage by the turns ratio of the primary to the secondary coil.

A simple Tesla coil could be made from an electromagnetic door buzzer, below.

(Buzzer, from http://radiology.rsna.org/content/suppl/2011/03/16/radiol.11101899.DC1/FigE2.gif)

Though the battery might be just 1.5 volts, a 60-volt neon lamp could be lit by connecting it to the contact and spring strip. Here, the high voltage is due to the high dv/dt as the moving spring strip suddenly opens the circuit. Winding a secondary coil with many more turns over the existing primary coil would increase the output voltage on the secondary by the turns ratio. Placing the right value of capacitor across the primary coil to tune it to the self-resonant frequency of the secondary would increase the voltage yet more.

See http://en.wikipedia.org/wiki/Tesla_coil and http://www.hvtesla.com/tuning.html for more information.

Bart Bresnik

via email

Go to the following web site by Kevin Wilson. It is very well done and has a nice and brief explanation of the theory of operation and how to build it safely. http://www.teslacoildesign.com/

Phil

Mt Airy, MD

I'm constantly replacing flashlights because of swollen D cells that expand and get stuck in the flashlight barrel.Is there some way to remove the cells without ruining the flashlight or splattering battery gunk all over?

#101311

Mitchel Westervelt

Denver, CO

Please log in to post an answer.

Answers

Let's first try to understand why a battery cell expands and leaks. Most battery manufacturer's say that this happens ONLY to discharged batteries. In other words, the battery chemical reaction has completely run its course and the chemicals now in the battery are not the original chemicals anymore. The discharged version of the chemicals will eat their way out of the casing and/or expand the casing due to out gassing.

Understanding this, we understand that we MUST NEVER allow the batteries to completely discharge before removing them from the flashlight or child's toy, or whatever. I'm sorry to say, that if you've let the batteries expand so much that they are stuck in the flashlight, the best you can do is to take the bulb out and throw the rest away. But, with a little forethought we can plan for this problem!

The first and best solution is to check your batteries every 6 months and as soon as they start showing any signs of decomposition/leaking, replace ALL of them.

The second solution is to use the new NiMH long shelf life batteries. Since these are rechargeable the chemical reaction does not cause them to expand, and since they are long life you only need to charge them once a year.

The third solution is to buy C-cell to D-cell conversion cases. I've seen these but do not know if they are still available, if you can find them let me know, I believe I saw them in one of my electronics or computer-parts magazines. In any event, use C-cells in these and when they expand they will have room to do so. If you're very lucky you'll be able to clean out the conversion case and reuse it.

I use the first and second solutions at my house, but I also only have one D-Cell flashlight, the rest are the new three AAA cell LED type. When they leak or expand, I can remove them since they are in a three-cell holder that slips into the flashlight. They are as bright as most older standard three D-cell flashlights or brighter, and they last far longer! So far I've always been able to get the case and holders cleaned up enough to use them again. And, if I ever lose one I won't lose much since I only buy the ones that are less that $10.

I hope that helps in preventing this problem for you.

Philip Karras

via email

Do an Internet search under "repairing Maglites". You'll find several sites with instructions and/or videos to help you in this endeavor. Look at them all before proceeding.

Dean Huster

via email

As far as controlling the LED brightness, here are two possible solutions: one using PWM (pulse width modulation) and the other a variable DC power source. First, I'll describe the PWM circuit in Figure 1 which is controlled by a PICAXE 08M microprocessor. The output from a PWM generator is programmed to run continuously. The timing duration is controlled by the ADC reading on potentiometer R1. The LEDs are controlled by FETs Q1 and Q2. All parameters are set by the programming code.

As far as controlling the LED brightness, here are two possible solutions: one using PWM (pulse width modulation) and the other a variable DC power source. First, I'll describe the PWM circuit in Figure 1 which is controlled by a PICAXE 08M microprocessor. The output from a PWM generator is programmed to run continuously. The timing duration is controlled by the ADC reading on potentiometer R1. The LEDs are controlled by FETs Q1 and Q2. All parameters are set by the programming code.