I am interested in building the shortwave radio shown in the schematic https://www.nutsvolts.com/uploads/wygwam/TF_2154_SW_Radio.jpg from Michael Williams Tech Forum question #2153 on page 78 of the February 2015 issue. However, I need more information, specifically the dimensions of L1 — length, diameter, etc., and the frequency range of the receiver.

I’m also seeking information on the coil data, size, number of turns, etc., for the shortwave and broadcast band coils for the Allied Space Spanner regenerative receiver, as well as modifications (plug-in coils VFO) that would increase the frequency coverage above and below the stock range of 6 to 12 MHz on the shortwave section of the receiver.

#6152

Bradley Flener

Central City, KY

Please log in to post an answer.

Answers

First I cannot help you with the information you are looking for on the Allied Space Spanner receiver. However, the other part of your question is about calculating the information for coil L1. The formula for calculating inductance needed for a resonate frequency as the value of the capacitor is shown.

To calculate the inductance of L1 for the standard broadcast band (535KHz to 1700KHz), L= the inductance in µH, f= the frequency in MHz, and capacitance is in pF. Since the capacitance is given as 10 to 365pF, and we know the minimum frequency is 535KHz (or .535MHz), L=25330/(.535 x .535 x 365). L=242µH. In the above formula, we replace the C an L can be interchanged. So if we know the value of the capacitance we can calculate the value of the inductance and visa versa.

With the calculated inductance (242µH) and the maximum frequency of the broadcast band (1700KHz or 1.7MHz), C=25330/(1.7 x1.7x242). C=32pF. So, with a coil wound very close to 242µH, the receiver would cover the standard broadcast band, and a little higher.

Let’s now calculate the number of turns of #30 and diameter of the coil needed to get 242µH. N=√(L(9r+10l) )/r is the formula for calculating the number of turns on a coil, but we have to know the values of radius, and the length of the coil. With a coil, the larger the diameter and the closer the turns are together increases the inductance. r = the mean radius, l = the length of the coil.

I recently did a project very similar to this so I have first hand knowledge of the approximate dimensions of the coil. Looking in a wire table, I find that #30 wire will make approximately 90 turns for a linear inch. I then choose the l of the coil of 1 inch long and the diameter to be 2 inches, so r=1. After plugging the values into the formula, 67 turns is the result. So close wind 67 turns of #30 wire on a 2 inch diameter form and then loosen the turns slightly, and spread them out so the length of the coil is 1 inch. With this information you can calculate the other resonate circuits.

Ned Stevens K7ELP

Saint George, UT

L1 value us very close to 250µH. You could wind one on a form, but buying on would be much easier as the magnet wire may be much more expensive.

Ned Stevens

St. George, UT

I have a drill press that has a five amp fuse that recently has started to blow on just about every project. I am not working on harder material and the bits are sharp, so I don't think its increased torque from friction which leaves the electronics. As this is simply a motor and a power switch, I can’t imagine what might be causing the increased current draw. Suggestions?

#5154

Liam Olivo

Saginaw, MI

Please log in to post an answer.

Answers

One thing that was not mentioned was a start run capacitor. Does the motor have a "hump" on it? If it does, there is a capacitor under it and it is probably bad. You can check it with an ohm meter when it is disconnected. See if the capacitor has not charged and causes the ohm meter to give some funny reading, like a negative reading. If it is shorted or open it is defective.

Doug Chason

Auburn, AL

Mr. Olivo is experiencing nuisance fuse blowing in his drill press. The problem may well be that the fuses that he has been using cannot tolerate the inrush current demand of the motor. At the instant of power application, the magnetic state of the motor core may be such that the first half-cycle of utility power drives it into saturation.

Assuming that the fuse is a 1/4” x 1-1/4” cartridge fuse, a Bussmann MDL-5 fuse will open at five amperes, but will tolerate more than one hundred amperes during a one-half cycle of utility power. See the time-current curves for this family on data sheet #2004, which is downloadable from web page www.cooperindustries.com/content/public/en/bussmann/electrical/products/electronic_smalldimension/elx_1_4_x_1-1_4_/mdl-v_mdl.catalog_numbers_(amps).brands.cooper_bussmann.html

If the fuse is another size, check with your local electrical jobber for an appropriate fuse having similar inrush tolerance. Good luck.

Peter A. Goodwin

Rockport, MA

Does the dill press sound any different? Maybe the bearing in the motor is wearing out causing the increased load.

What about the cord? Has it been pinched/damaged in any way? Or even the outlet that it is plugged into, are there visible signs of scorching?

Lastly, how old is it? Could the motor be electrically failing? Things to consider beyond stresses due to operator use.

Justin J

King City, CA

If this is just an on/off, switched drill press, then you definitely have an excessive friction issue. If a good lubrication doesn’t help, then the brushes or commutator in the motor are worn and binding.

Michael Herman

La Quinta, CA

Worn bearings could be allowing the armature to rub on the stator. Remove the belt and try to move the motor shaft; if it moves at all, it is bad.

Russell L. Kincaid

Milford, NH

:You don't say what type of fuse you are using but if it is a buss type glass fuse, you might want to make sure you are using a slow-blow type fuse for your drill press.

Gene Sellier

Fairhope, AL

Is there a simple circuit that would allow a normally open pushbutton to turn on a relay when pressed, and then turn it off when pressed again?

#5153

Isaac Wright

Maumee, OH

Please log in to post an answer.

Answers

When the circuit is first energized, C charges to 1/2 Vcc through voltage divider R1/R2. When the button S1 is pushed, C discharges through the relay coil. It pulls in, and the relay is held closed by the current through R1 and the relay coil. When the button is pushed again, C, now fully discharged by R2, goes across the relay coil making it drop out and returning the circuit to where it started.

Mike Callaghan

via email

In essence, this is a flip-flop. Push the button and the state of the flip-flop will change. Adjust the values to your needs.

Al Jaszek

Needham, MA

It’s funny you should post this request. I just happen to have an article submitted to Nuts and Volts utilizing this exact same situation that will hopefully be appearing in an upcoming issue!

In the meantime, here is the (modified) relevant portion of the schematic as you requested. The 74LS109 is a J-K Positive-Edge Triggered Flip-Flop. The input is tied to normally tied to ground, but when you press the switch that input is momentarily brought high, triggering the flip-flop, toggling the relay between it’s on and off states. R2 and C1 are to debounce the switch and prevent multiple false inputs.

In the meantime, here is the (modified) relevant portion of the schematic as you requested. The 74LS109 is a J-K Positive-Edge Triggered Flip-Flop. The input is tied to normally tied to ground, but when you press the switch that input is momentarily brought high, triggering the flip-flop, toggling the relay between it’s on and off states. R2 and C1 are to debounce the switch and prevent multiple false inputs.

Derek Tombrello

Columbiana, AL

Use the push button switch to toggle a JK flip-flop.

Lance Corey

via email

It can't get any simpler than two resistors, one capacitor, and the relay.

Mike Callaghan

La Crescenta, CA

Here is a simple circuit that can be used to toggle a relay using one switch. A relay with a 12 VDC is used however the relay contacts can control a larger voltage if needed.

Craig Kielhofer

Wheeling, IL

Look into a switch debouncer such as the MAX6816 and JK, or T flip-flops to drive the gate of a low side switch on your relay. The output of the switch debouncer could drive the clock of a T, or properly configured JK, flip-flop. Don’t forget the protective diode across the relay in order to clamp the voltage when turning the relay on/off. I hope this helps.

Justin J

King City, CA

Here are two circuits that should do want you want: Grove-2 @10 from: www.seeedstudio.com (YES, there are 3 e’s) Cebek I-9 @ $4 from www.mcmelectronics.com

Also, there are a variety of electro-mechanical relays available at many sources. These do not need a circuit to latch but when the relay is activated, it toggles a switch from off to on.

Michael Herman

LaQuinta, CA

In a recent issue of NV, Roger Secura wrote the article “How to Use a Transistor as an SPST Switch.” My question is how can an STDT switch be made using transistors, FETs, or other non-mechanical components? If it is possible, please post a circuit.

#6151

Don Czyzyk

Santa Clara, CA

Please log in to post an answer.

Answers

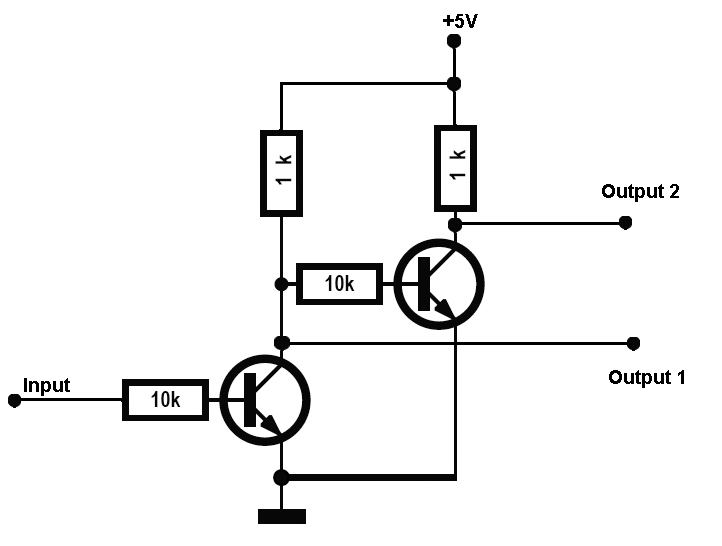

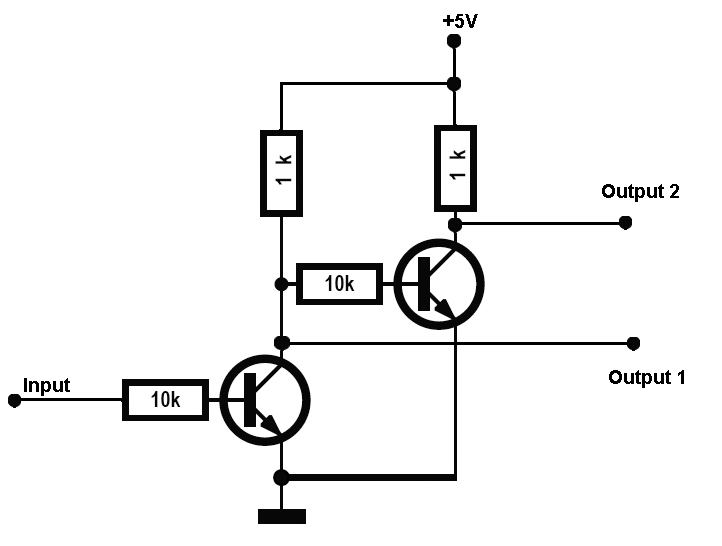

It’s pretty simple... you just need another switch that’s connected to the output of the first switch. These switches are commonly called Inverters, meaning that the output is inverted from the input. This means that for a high level input, the output is a low level, and vice-versa. So, all we need to create a bi-level output from a single input is a second inverter connected to the output of the first inverter. Bipolar transistors and FETs act pretty much the same way, the difference being that bipolar transistors are current-driven, whereas FETs are voltage-driven.

If you need more theory on transistor circuits, I refer you to a series of articles by Ray Marston in Nuts&Volts titled “Bipolar Transistor Cookbook”. This is an 8-part series that N&V has graciously made available online. www.nutsvolts.com/magazine/article/bipolar_transistor_cookbook_part_1. Be sure to have plenty of reading time available, because it contains a train-load of information. I’ve attached a circuit image depicting how to connect two transistors as an SPDT switch.

David Mason

Hazel Green, AL

What would be the most efficient way to reduce the voltage from a nine volt battery to 5V? I could use a 7805 but it seems to bleed off a lot of power as heat. Is there a more efficient circuit or part?

#5152

Alan Vallo

Piedmont, SC

Please log in to post an answer.

Answers

Take a look into DC-DC buck converters. Many of the IC manufactures offer low part count devices, and depending on your load requirements, may offer a completely integrated solution.

Things to consider when selecting your buck converter:

1. Internal switch/es to the IC — ease of implementation

2. Synchronous design — higher efficency

3. Load capabilities — This is one of the most important things to consider, especially with an integrated design. You want to select an IC that meets your load requirements, ie output current, but not something that blows them out of the water.

In other words, If your output requirements are 5V @ 100mA (0.5W), don’t choose a device capable of 10W, or 2A at 5V. The reason being is, these devices are more efficient when operated at the loads they were designed for.

One last thing, review the EVKIT the manufacturer has available for the device. These are really good starting points for layout and design with the device. I hope this helps.

Justin J

King City, CA

A very economical solution are the LM25XX switching regulators on a board, which sell cheap from MPJA or the internet. I also use the MC34063 which is often found in the “12 volt to 5 volt” cell phone adapters at your local thrift store, but easier to work with purchased new.

For low current applications, my favorites are the encapsulated 1W or 3W switching DC-DC regulators from CUI, Murata, etc. via Digi-Key.

Jim Lacenski

Bellevue, WA

The UA78s40 is an old switching regulator that is obsolete, but parts are available on Ebay. The datasheet has a schematic for 26 volts to 10 volts but you only need to change two resistors for 5 volts output: R1 = 30K, R2 = 10K.

A more modern solution is the LM2576 buck regulator. It only uses two capacitors, a diode and an inductor for external components. The datasheet has a schematic that you can use directly.

The package is TO-220-5, Mouser part number is: 926-LM2576T-5.0/nopb, cost: $2.82. The IC is good for 3 amps but if your load is less than 20 mA, it would not be a good choice.

Russell L. Kincaid

Milford, NH

Yes, the 7800 and 7900 series seem to just dissipate heat to drop the voltage. Try the LM2940-5 - I found them at Jameco for $1.39 each......

Schneids

via email

You might try using an LDO regulator like the LM2596S chip. I bought a 1.5V-37V DC/DC buck convertor from MPJA for $1.95 to reduce 12V to 9V and it runs very cool.

Gene Sellier

Fairhope, AL

Can one of your experienced electronic engineers recommend replacement plastic transistors (maybe a la PN2907) which are easily available, in order to substitute Q1, Q2, Q3, and Q4? I want to totally eliminate 2SB54 transistors WITHOUT any draconic and/or extreme changes to the original diagram (below) for this (push-pull) phone amplifier I'm using, by attaching a suction cup to my (landline) phone's receiver.

I'm well aware of the existence of other phone amplifiers (built around the LM386) which are easier to build with fewer parts, but I'm only interested in this diagram, as I’ve already built it in the past — not only as a phone amp with ample volume (which also works very well as a P.A. system), but as a wired intercom.

#5151

Nate Franklin

Schererville, IN

Please log in to post an answer.

Answers

Mr. Franklin desires to reproduce a known circuit design that uses four 2SB54 transistors. The 2SB54 is an obsolete part. Furthermore, it is a germanium device. Mr. Franklin asks if a 2N2907 or similar silicon PNP device could be used instead.

Substituting silicon devices for germanium devices is a non-trivial exercise:

• The no-signal emitter-base junction voltage of germanium devices is about 0.3v, while that of silicon devices is about 0.7v. In a linear circuit such as that presented here, bias voltage appropriate to the transistor material type must be applied to overcome the junction voltage offset.

• Germanium transistors exhibit current leakage. This is often sufficient to provide self-biasing. Silicon devices have negligible leakage in the circuit under consideration, so external biasing must be considered.

The simplest thing to do is to replace the 2SB54 with another germanium part. The NTE100 device, manufactured by NTE Electronics, has characteristics that are similar to those of the 2SB54. It is available from multiple distributors including Newark Electronics, Fry’s Electronics, and Online Components, or you might try eBay. Pricing runs from about four to seven dollars per device. A data sheet, which includes a basing diagram, is available from NTE Electronics.

Good luck.

Peter A. Goodwin

Rockport, MA

Those transistors date back in time quite a ways, as does the circuit! The 2SB54 is a Germanium, PNP unit. RadioShack has a drop-in generic on their website as part #55051964.

You could also toss out everything between the microphone and the speaker and connect a LM380 integrated circuit. I have an old transistor substitution guide in storage so contact me if you need a further referral. Good luck.

Michael Herman

LaQuinta, CA

Q1 and Q2: the circuit is a self-biasing design. MPSA56 should work fine, even though these are silicon transistors instead of germanium.

The output stage (Q3/Q4): 2N4918 or BD136 would be my preference. You will need to increase the value of R6 (try 330 ohms) to reduce crossover distortion due to the larger Vbe drop of the silicon transistors. Note that this output stage has no temperature compensation and is subject to thermal runaway.

Better transistor designs of this era used a thermistor for temperature compensation. See Wikipedia’s thermal runaway entry, bipolar junction transistors, for more insight. I would still LM386, which eliminates the (likely) hard to get transformers too. More power? Look at the numerous class-D single chip power amps.

Jim Lacenski

Bellevue, WA

The circuit is well designed with feedback in the first stage to stabilize its current and an emitter resistor to limit the current in Q2. The output transistors, Q3 and Q4 are class B so draw no current until driven by audio. I simulated the Q1, Q2 circuit and it works perfectly with no changes using 2N2907 transistors. Q2 collector current is 4.8 mA which is sufficient to drive the output transistors to watts of power.

Russell Kincaid

Milford, NH

The main problem is the transistors are germanium and not silicon. So, I doubt you could plug in silicon transistors and have it work properly [although if you’re desperate, you might give it a try anyway].

The transistors have pretty much been discontinued from what I could tell. NTE makes a sub that should work for you — NTE102. You should be able to find them at several places. I checked Allied and they had some in stock — but on the pricey side.

You should be able to find a newer circuit at some electronics site that uses newer transistors or op amps.

Schneids

via email

I would consider the 2N3906. The Hfe (100 min, 300 max) puts this device near the 2SB54 specified Hfe of 140.

Mark Strauch

Livermore, CA

The 2SB54 is a fairly ordinary Germanium PNP transistor. It could be replaced with any general purpose Silicon PNP like the PN2907, 2N3906 or BC327. You will need some changes as silicon transistors are harsher than germanium types:

(a) you will have to increase the value of R6 to 1K to bias the output stage (maybe 1K5 to get more power out) keep an eye on the quiescent current, it should be < 10mA.

(b) (optional) to improve crossover distortion , remove R5, and use 33K resistors between base and collector of each of Q3 and Q4 (just like R1)

(c) (optional) to make it less tinny, put a 22ohm in series with C3 (other values will work like a tone control)

(d) (optional) to flatten out the response , try a 47K for R1 , (values in the range 10K to 100K could be tried) this also affects the gain and interacts with the source impedance. The above values were determined by simulation to give a better result than the original values, however the simulation uses perfect transformers. If you get RF oscillations, try a 1nF from base to collector of Q2 or 470pF from base to collector of Q3, Q4, or ferrite beads on the emitters of Q1 or Q2.

Bob Turner

Salamander Bay, Australia

The swap you suggest will require some adjustment of transistor bias. The 2SB54 are Ge. material with 0.15 to 0.2V base emitter bias. The PN2907 and similar are Si. with a 0.65 to 0.7V base emitter bias requirement. R2 and R6 will likely need to be increased in value. Quick estimate for R6 at 0.7V is around 1.2K The collector feedback biasing makes the calculation of R2 value more difficult and might not have to be changed due to the feedback.

Search for similar circuits using silicon transistors to get some better resistor values. Note that Q3 and Q4 require a little forward bias to prevent crossover distortion. I would expect considerable distortion if the biasing resistors are not modified to account for differences in GE. vs. Si material GWS

George Shaiffer

Colorado Springs, CO

A 2N3906 should work OK. It has the same general characteristics as the 2SB54 transistors, except for being silicon instead of germanium, greater power dissipation and slightly higher hfe (100 as opposed to 80).

Gene Sellier

Fairhope, AL

I would try a PN2222 which is an old standby PNP transistor. I don’t think there is anything special about the 2SB54, it is just older. Jameco sells them for ten cents a piece. Part no. 28628. Download the data sheet and watch the pin locations.

Ron Newton

Carson City, NV

I have a Marlin P. Jones DC motor speed controller (Part 31566MD, 6-24 volts, 20 amps max). I need to add an over current circuit to it. I inserted two 0.1 ohm/five watt resistors in series with the motor –lead and the M-connection on the controller. My scope displays a steady 0.6 volts DC level across it. The PWM waveform changes from 2 µsec to 40 µsec in length as the output of the speed controller is increased from 0 to 3 amps, while my DVM displays 0.02 VDC to 1.3 VDC for the same range of output.

So, the question is “What kind of circuit can I add across the resistors to get a VDC reading?” I have tried an NPN transistor, base lead to the motor –lead, and the emitter lead to the M- connection. (With a 10K collector resistor to +12 VDC.) The collector voltage went from +12 volts to +3 volts as the controller output went from 0 to 3 amps.

Next, I connected the collector voltage to an LM324N quad op-amp set up as a voltage comparator. The +lead of an LM324 went to a 200K pot, connected between +12 VDC and Gnd. The transistor’s output went to the –input of the same op-amp. A 1M ohm resistor is connected from output to +input for hysteresis. (This output should go high to set a CD4013N flip-flop at an over current condition.)

The problem is that the output of the op-amp’s output does NOT change at the point when the voltage at the +input is greater than the –input. The op-amp’s output changes as the voltage from the transistor decreases. I used the LM324N auad op-amp because it has four op-amps in one chip, and it works with a single +12 VDC supply. It would be helpful if the new circuit could use it also, but not necessary. I could use a PIC16F628 or an Arduino Nano, if you design with them.

#4153

Patrick Fleming

Hoffman Estates, IL

Please log in to post an answer.

Answers

I’ve found the 31566 schematic. The simplest solution, that I’ve used in similar circuits, is to use a ZXCT1009, this is a 3 terminal current sensor. So put your 100mR shunt in the positive line, attach the ZXCT1009 across it, and a current proportional to the motor current (about 1/1000 actually) flows out of the third pin to ground. Simply attach a resistor, say 1K ohm to ground and you can read the motor current off this.

The most important advantage of this chip is the sense resistor can be grounded at the Arduino, so you won’t be measuring any errors due to voltage drop in the ground wiring. The datasheet shows how to use it, and provides calculations on how to use PCB traces as current shunts.

Bob Turner

Salamander Bay, AUstralia

Anyone know where I can purchase small quantities (25 ft rolls) of the different color jackets of good Beldon or (?) 65/30 test lead wire? I see it in 100 ft rolls $$, 10 colors, but that would be over a $1,000 for all ten.

#4152

Terry Arnall

Hayward, CA

Please log in to post an answer.

Answers

Try Elenco WK-106 Hook Up Wire kits which has 6 colors (red, yellow, black, white, green, blue) of 22 gauge wire in 25 foot rolls for around $15. See the web site Elenco WK106 Hook-Up Wire Kit 6 Colors.

Tim Brown

Honea Path, SC

I have been tasked with the chore of replacing 300 watt incandescents (5900 lumen). How many of what kind of LEDs and current-limiting diodes in series/parallel do I need to fool the human eye into thinking it is seeing a brighter, more pleasant level of lumens?

#4151

James McFadden

St. Maries, ID

Please log in to post an answer.

Answers

I am going to try to answer your question from the standpoint of a person solving your problem on a contractual basis, and who, therefore, must deliver the best design at the lowest cost. I think that this is the most objective, efficient way to approach the problem and to give you a reasonable answer.

With all due respect, you have left out important — or included ambiguous — information needed in order to arrive at a design which meets your exact needs.

For example, you have not specified any type of physical form factor. Do you want to replace a single 300-watt incandescent bulb, or an array of bulbs emitting 5900 lumens? What do you mean by “fool the human eye into thinking it is seeing a brighter, more pleasant level of lumens.”

Regarding the latter:

White LEDs come in a minimum of two different colors — warm white (color temp. approx 2800K; simulates incandescent output), and cool, or bright, white (color temp. approx. 6000K; just about simulates daylight and fluorescent lighting). These LEDs are very commonplace, being available from, among other sources, www.superbrightleds.com, Amazon, and others. Just make certain you buy from a reputable source which will stand behind its product.

One could certainly design and build for you a light (lights?) meeting your specific requirements, using readily-available 100-watt LEDs (warm white or cool white), along with the appropriate power supply AND — most importantly — cooling. VERY SERIOUS cooling.

As the situation stands currently, my suggestion to you is the following: LED technology, and the LED lighting industry is very mature; so much so that there is no need for an individual, or firm, to waste his or its valuable time designing a high-power LED lamp or lighting fixture which has

(a) most likely already been designed, or

(b) which can be easily adapted to the user’s specifications from an existing design of a reputable LED lighting manufacturer (you may be surprised to know that, as of this moment, LED “drop-in” replacement lamps are available to replace standard fluorescent tubes, while providing the very much longer life and very low power requirement of LEDs).

If I were you, I’d start by putting out feelers to companies such as www.superbrightleds.com, who have already designed, and offer for sale all types of lighting solutions.

I realize, as a tinkerer, hacker, and design engineer myself, who loves nothing more than to make something useful out of a pile of components, that this solution is somewhat distasteful.

You CAN design a solution yourself, if the situation warrants. You CAN do it. BUT... if you’re attempting this for reasons other than self-satisfaction, then save yourself time and money, and go with the solution which the experts most probably already have.

By the way, just in case the fact escapes you — Due to the semiconductor physics involved, LEDs at the output level you need do not provide any significant power savings over incandescent technology, or other lighting technologies, for that matter. Three LEDs capable of a total output in the range of 5500 to 6000 lumens will require power of approximately 100 watts each. Total = 300 watts (not including active cooling), the same as the incandescent you want to replace. If you’re thinking that the much longer life of SMALL semiconductor LEDs justifies the transition, you should know that the jury is still out on just how seriously the lifetime of high-powered LEDs is affected by the heat that is generated by the current required for all this super-brightness. Some of the jury think it’s end-game, for now, until there’s a major breakthrough in LED technology.

John Colt

via email

I recently replaced twelve 300-watt incandescent lamps with LED floods. In my case, it was made easier because the 300-watt lamps illuminated hanging lamp enclosures in a church. The overall purpose was to provide reading illumination for the congregants.

If this application suits your purpose, look at Lighting Science DFN38WWV2NFL120, being a 120V 24-watt PAR38 lamp, 3000K. These lamps, while only rated at 1300 lumens, put all of their light output in one direction —downwards — while the incandescent lamps spread their 5900 lumens all over the room. And they’re dimmable. It was a no-brainer for us because they worked in the application and the electrical demand for the lighting went from 3600 watts to 288 watts.

One on-line source is https://www.1000bulbs.com/product/63140/LED-PAR38242530.html, but your local electrical supply jobber might get you a better price — especially if your state is currently giving rebates for so-called “green” appliances.

Peter A. Goodwin

Rockport, MA

In a recent thunderstorm, a nearby lightning strike took out some of the electronics at my neighbor’s house. Is there anything a DIY'er like me can build to protect my delicate electronics — other than unplugging everything? Something with MOVs maybe?

#3152

Matthew Hodges

Wichita, KS

Please log in to post an answer.

Answers

Their is also a whole house surge-protector from Square D and other electrical panel suppliers for less than $150. They hook up to both sides of the 220 volt buss bars. Check you panels maker site. I purchased one a number of years ago and it stopped electrical line spikes. With a cable and phone line surge-bar I have been lucky and keeping my replacement money in the bank.

George Jones

Hopewell,VA

The simplest solution to lightning-induced surge protection is to use a commercially available surge-protected outlet strip. There are numerous sources for these items, and you may even find a suitable device at your local hardware store.

The important thing to understand is that a lightning strike conducts huge oscillatory currents. A varying electrical current will generate a changing magnetic field, which in turn will induce superimposed voltages in nearby conductors -- including service drops from the utility pole to your house (e.g., electrical power, TV/internet cable, and telephone). Such surges can be induced both line-to-line and line-to-ground in the electrical power service drop (and for balanced-line applications such as telephone). Properly-designed surge suppressors provide both line-to-ground and line-to-line protection for such circuits.

Surge voltages induced line-to-ground arise because such devices often are connected to more than one source of surge voltage: For example, your television set is connected to utility power and also connected to the TV signal cable. Likewise, your computer may be connected to utility power, to a cable from your internet service provider, and to a telephone cable (for fax service). Unless these cables/wires are all run together throughout the house (and this practice is discouraged due to the possibility of capacitive cross-coupling), one or more loops exist, and within each loop, the surge voltage induced by the lightning strike is a direct function of the areas enclosed by the loop.

It follows that effective surge suppression can only be accomplished by feeding all of the incoming electrical services through what is called a "surge-protective window". In such a structure, surge suppression elements such as metal oxide varistors (MOVs), avalanche diodes, or gas tubes can clamp impulse voltages to a common reference point plane which in turn is connected to earth ground. This can be effected by using a surge-protected outlet strip that also incorporates protection for telephone and cable lines. Typical examples of this all-inclusive surge protection are devices available from Belkin (e.g., www.belkin.com/us/BV112234-08-Belkin/p/P-BV112234-08/) and Tripp-Lite (e.g., www.tripplite.com/av-home-theater-surge-protector-isobar-10-outlets-8-ft-cord-3240-joule-3-line-coax-ethernet-tel-network~AVBAR10/).

All cables exiting the surge suppressor block should be run together wherever possible, secured periodically by twist-ties or other means. This method ensures that negligible induction areas exist into which surge voltages can be introduced. Capacitive-coupled interactions are no longer a problem because any prior surge voltages have already been stripped from the cables by the surge suppressor block.

Please note that the protectors identified above are "Cadillacs" because they provide surge suppression for all common power and media transport wiring. Sometimes just a simple one-outlet surge suppressor will do the job — or, for example, a single-outlet suppressor with built-in telephone line surge suppression, both at significantly lower cost. I even use single-outlet surge suppressors to protect my coffee maker and washing machine because each of these devices contains electronic modules that are expensive to repair.

The important consideration is to maintain the "surge protective window" approach to the problem as outlined above.

Peter A. Goodwin

Rockport, MA

Lightning protection is a complex issue, including home entrance cable protection, bonding of large metallic structures, and even grounding of rain gutters and downspouts. A good place to start is a free PDF from www.lightningsafety.com/nlsi_lhm/IEEE_Guide.pdf. Because a lightning bolt can pack a 500 MJ wallop, far beyond any MOV rating, surge protectors are not protection against a direct strike, but they do help limit inductive surges (e.g. lightning hitting a tree nearby, inducing a current in house wiring). In brief, running a hefty ground wire from gutters, external antennas etc. to an effective ground in conductive soil is the first line of defense.

MOV surge suppressors have saved my PC and appliances from one damaging surge, though, as shown by blown internal fuses and smoking MOV's!

B. Bresnik

via email