With TJ Byers

Motor Remagnetizer

Question:

Almost 50 years ago, the US Navy taught me about DC motors: how too much current can demagnetize a motor, about keeper bars if an armature must be removed, and a lot more. I know this is also true for stepper motors according to present-day manufacturers literature. For 45 years, I've never used this information, but now I have some N-scale DC motors that need to be remagnetized. Have you or will you consider a short treatise on this subject?

Al Hooper

Warner Robins, GA

Answer:

The term "permanent" magnet is somewhat misleading, in that heat, vibration, and reverse "EMF" can weaken its magnetic field over time. For a motor to develop full torque, it is necessary for the magnets to be saturated, or fully charged. No matter how a magnet's strength is lost, it's just a matter of time before you'll be forced to fix the problem or replace the motor.

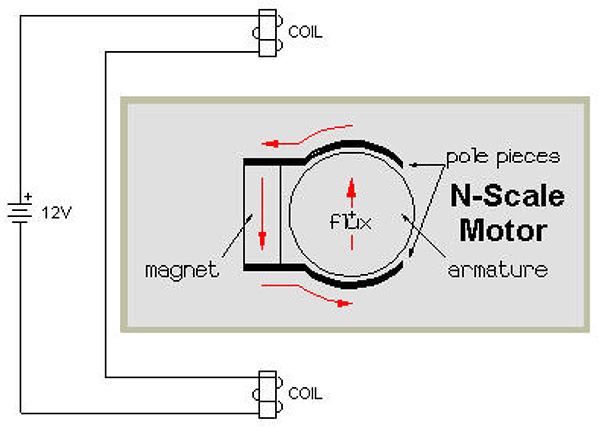

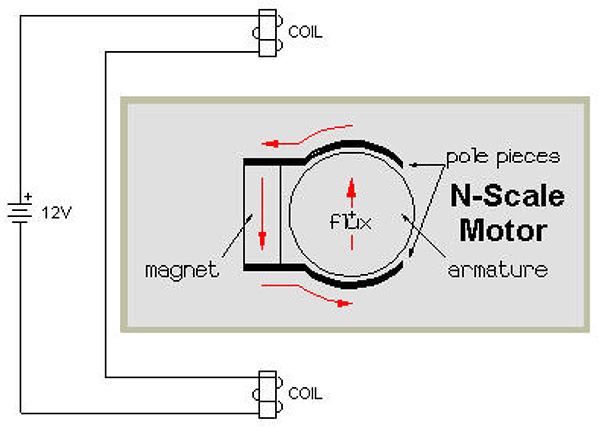

The fix, as you point out, is to remagnetize the motor. This is typically done by placing the motor sideways, positioning the magnet between two very strong electromagnetic poles, as shown below. The most common DC motor of this kind is called the side magnet, open-frame motor, also shown.

Now the hard part is deciding just how strong the electromagnet has to be to restore the old magnet. Fortunately, there is no such thing as too strong a remagnetizing field, just not strong enough. A permanent magnet can only hold so much magnetism, which is determined by its chemical structure. Exceeding that limit won't make the magnet any stronger, but it won't hurt it either. I can't say how much is enough, but I've heard that one pound of #16 enameled wire wound on a 1/2-inch soft iron core (which can be salvaged from an old power transformer) produces a suitable field. Typically, this is 14 turns of wire, 14 layers deep. You will need one coil per pole. Wire the two coils in series, insert the motor, and momentarily connect them to a fully-charged, 12-volt car battery. If this doesn't work, increase the voltage or the number of turns -- or check your magnet alignment. Oh yeah, make sure you have the correct polarity, or the motor will run backwards. (Fortunately, no damage is done; reverse the battery terminals and zap it again.)

Servo and stepper motors, too, suffer the same malady. However, the fix here isn't so easy because of magnet alignment. When refurbishing one of these devices, I suggest sending it to a "tune-up" shop, like those listed below.

A-1 ServoMotor Repair

www.servorepair.com

Servo Repair International

www.motionshop.com/repair/sri.shtml

Comments